Free Septic System Inspection ($99 Value) Free enzyme treatment, Financing Available

Request Service Now!

407-565-7044Free Septic System Inspection ($99 Value) Free enzyme treatment, Financing Available

Request Service Now!

407-565-7044

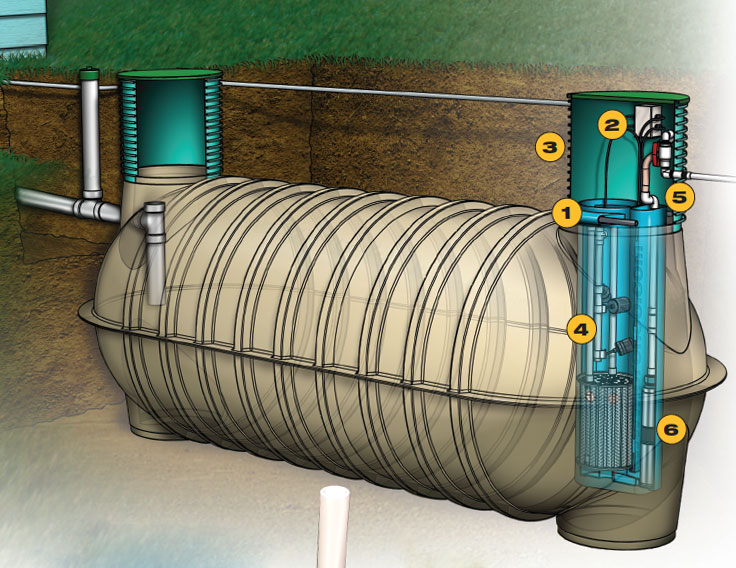

Lift stations play an indispensable role in wastewater management systems, making an understanding of their components essential to both homeowners and professionals like Septic Blue of Orlando to keep systems functioning effectively. From septic tank pumping to repair projects or even new installations, knowing all there is about lift station components will prove useful in your decision-making processes.

A lift station or pump station, commonly referred to by its acronym LPS for short, is designed to transport waste from lower elevations to higher ones when gravity flow alone cannot do the trick. This is often required in areas with uneven terrain or where sewage systems must traverse valleys or low-lying areas.

At the core of every lift station lies its pumps. Sewage pumps play an integral part in moving wastewater out from its source to a higher elevation, and depending on their design, they may either be submersible or dry-pit. Submersible models are more suitable for smaller systems because they are installed below water level. At the same time, dry-pit options have their own dedicated chamber to make maintenance simpler and quicker.

A wet well is a basin in which wastewater collects. Pumps draw the water out from this wet well to be processed through your septic tank system, with its size depending on expected volumes of wastewater production. Proper care must be taken with regard to maintaining and cleaning out this wet well in order to maintain efficient functioning and ensure the efficient performance of its pumps and machinery. Regular inspection and septic tank pump outs may help ensure smooth and safe operations of its pumps and wet well, including regular inspection, septic tank cleaning, and maintenance programs to help avoid buildup in both places and maintain clean conditions to improve its performance as part of efficient overall septic tank operation and operation.

A control system controls the pumps by monitoring water levels in the wet well and activating pumps when necessary. More advanced control systems feature alarms and remote monitoring features to alert septic companies of potential issues before they become serious problems.

Floats and sensors can help detect water levels in wet wells by sensing whether or not water has reached certain thresholds in an underground wet well. When this level has been reached, a float activates a pump. Sensors offer more precise control options while modern systems often employ them for increased reliability.

Check valves prevent the backflow of pumped-out waste into the wet well, and gate valves allow manual control over the flow rate for use during maintenance or septic tank repair work.

Proper ventilation systems protect our environment from hazardous gases like methane. Lift stations usually include ventilation fans and ducts to maintain a healthy atmosphere for lift operation.

Alarm systems are essential safety features. They notify operators about high water levels or pump failure, helping avoid overflows or backups that require prompt tank pumping and maintenance services.

A reliable power source is essential to running an effective lift station, and many systems feature backup sources like generators to ensure uninterrupted operations even during power outages.

A piping system connects the lift station to other elements of the wastewater system. This includes inlet pipes that bring wastewater directly to a wet well for pumping out and discharge pipes that take it away after pumping has taken place.

Regular lift station maintenance is key to keeping it operating optimally, including cleaning of septic tanks, inspecting pumps and control systems, and testing sensors and floats properly. Here are some maintenance tasks:

Lift stations frequently experience pump failure due to electrical issues, clogs, or mechanical wear and tear. Maintenance services and prompt septic tank repair should help prevent such mishaps from happening again, but should an issue arise that needs fixing quickly, having it taken care of promptly can significantly reduce backlog issues.

Debris can block pumps and pipes, leading to potential clogs. Regular septic tank pumping and waste removal can reduce this risk; should one still occur, however, professional cleaning may be required for effective removal.

Sensors and floats may become stuck, leading to poor pump operation. Regular tests and cleaning can ensure they function as intended.

Unexpected power outages can halt lift station operations. Backup generators are essential during these periods, so it is crucial that regular testing takes place to ensure that they will be operational when they're required.

Understanding the components and functions of a lift station is vital in creating an efficient wastewater management system. Knowledge of these systems is invaluable for regular maintenance, troubleshooting issues, or planning new septic tank installations. A septic company's regular cleaning or repairs can ensure smooth operations for years. Septic Blue of Orlando can provide the expertise needed to keep lift stations functioning at optimal performance.

Taking care of your septic system might not be the most exciting job, but avoiding messy, expensive problems down the road is super important. A healthy system…

If you own a home with a septic system, you might wonder how long it will last. Most septic systems can work well for 20 to 40…

If you live in a home with a septic system, you know how important it is to keep everything running smoothly. One of the most important parts…

If you’re building a home or upgrading your waste system, one thing’s for sure: you’ll need a septic system that works properly from day one. Many think…